Many retail companies seek to maintain a customer-centric merchandising strategy: having the right product in the right place at the right time. It’s a smart strategy, though not always easy to achieve, as it requires certain advanced capabilities working in sync with each other.

Two of the key processes in this strategy are allocation and replenishment. In this article we explain what they are, what are the main challenges in their operation and how you can overcome them to achieve greater efficiency and profitability in your retail business.

Allocation and replenishment: two of the key processes in retail.

These two processes are key to retail stock management, ensuring that the right products are in the right quantities at the points of sale where they have the best chance of selling at full price.

Achieving this is crucial for retail organizations to achieve their sales objectives and maximize their bottom line, all while ensuring customer satisfaction.

Let’s take a closer look at each of these processes.

What is allocation.

Allocation is the process by which initial units are distributed, either at the beginning of the season or during the launch of a new product; certain quantities of items are allocated to specific stores, based in many cases on an analysis of historical sales data. It also considers the stock to be left in stock for future re-shipments.

In other words, it seeks to optimize the distribution of stock for new launches or seasons at points of sale so that initial demand is covered, while minimizing excess inventory and stock-outs, in order to maximize profitability.

As we said, this process is based on historical data, although this is sometimes not enough, for example when there are new products to incorporate in a season. In this case, how are they distributed, in all stores equally or in the most flagship stores, distributing all sizes equally or following a size curve?

We will talk about how to solve this problem later, but first let’s talk about replenishment.

What is replenishment.

Replenishment can be defined as the process of acquiring products on a recurring basis for store replenishment. For this task, the inventory in warehouses is counted and distributed in a suitable way so that the points always have enough stock to cover the demand but without entering into points of excess or lack of inventory.

Calculating how much stock to deliver, the right timing and how to distribute it among the different stores is the challenge to be solved here, a task that is complex due to the high number of SKUs that are usually handled.

Main challenges of allocation and replenishment in retail.

As we have seen, these processes play a fundamental role in retail stock management, and their effectiveness (or lack thereof) has a significant impact on profitability.

As we have already mentioned, these tasks have a series of challenges that make them not easy tasks. Some of these main challenges to solve when we talk about allocation and replenishment are:

- Handling large volumes of data: from sales history, inventories, store performance, trends, different geographic areas, etc. The volume of data means that tools such as spreadsheets fall short and it is necessary to use other types of solutions.

- Lack of data integrity: having inaccurate data (or no data at all) can lead to decisions that have a very negative impact, causing problems such as stock-outs, overstocking and, as a consequence, loss of sales or profitability.

- Having sales forecast data and consumption patterns: these will be different for each store and for each product or group of products, and will be key to make inventory decisions.

- Manage inventory levels: the challenge is to achieve an appropriate level to avoid both overstocking and stock-outs, which requires careful planning and forecasting as well as the ability to make decisions in an agile manner.

- Communication and collaboration management: meeting the objectives of being efficient in store stock management requires the participation of various stakeholders both inside and outside the organization, so ensuring good communication and collaborative work is essential to achieve results in an efficient and agile way.

How to improve the allocation and replenishment process in retail.

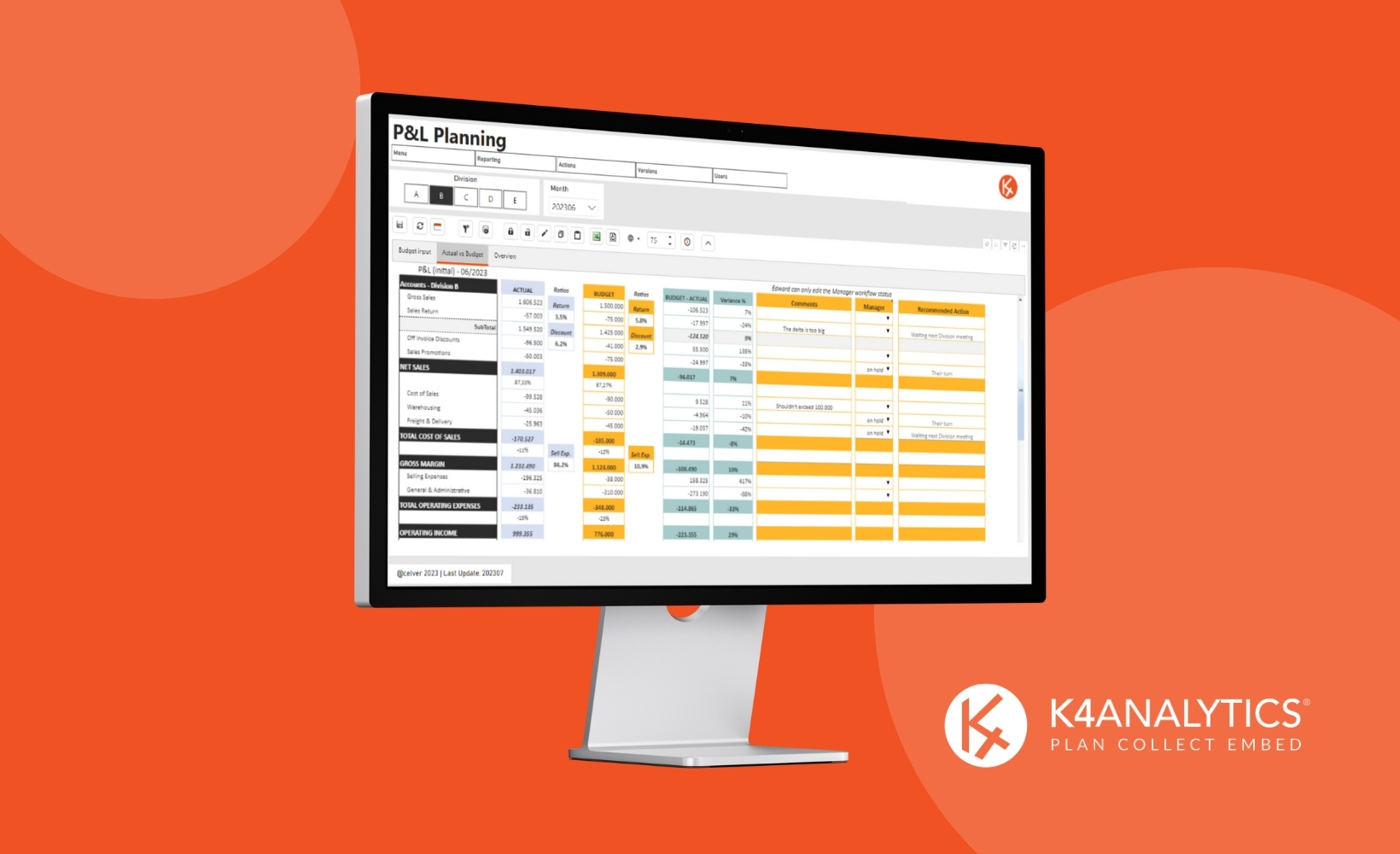

We have seen that the management of allocation and replenishment processes requires certain capabilities that generic software or spreadsheets do not reach.

Having a customized planning solution allows you to design and execute these processes with key advantages, such as:

- Ability to manage allocation at multiple levels of detail (category, sub-category, model, SKU).

- Ability to simulate initial allocations based on various parameters or by copying patterns with a mirror product, and then edit it if desired.

- Definition of a replenishment process suitable for each business/channel/country or even store, either by minimum units, by weeks of coverage, by probability of sale.

- Semi-automatic processes that save time by calculating the necessary goods to replenish taking into account minimum order, number of packages needed, lead time, etc.

- Processes connected between them (Allocation-Replenishment) and also with other key processes such as Open To Buy or Merchandise Financial Planning, all in the same environment and feeding each other.

In addition, a customized solution can provide real-time information on inventory levels, sales performance, product mix at the point of sale, etc., helping retailers to overcome the barriers and challenges mentioned above, and enabling them to make better decisions to achieve greater overall profitability.

A manual management of these processes for an organization with different points of sale, channels and a high number of SKUs is simply not feasible, since in addition to consuming a large amount of time and resources, it will be the source of errors that can have a significant impact on the results, as we have already mentioned.

Taking allocation and replenishment further through AI.

In addition to all of the above, if your solution has enhanced capabilities thanks to the integration of artificial intelligence (AI), your capabilities will increase even more, allowing you to achieve:

- More accurate demand forecasts: thanks to the power of predictive AI you will be able to know future demand for each store and product, allowing you to reduce risks and allocation costs.

- More efficient inventory management: thanks to optimization models, you can minimize in-store stock without losing sales due to stock-outs, calculating shipments or rebalancing between stores.

- Increased efficiency throughout the supply chain: improving allocation and replenishment allows the entire distribution chain to be managed more efficiently, reducing transportation costs and delivery times.

- Greater sustainability: thanks to less transfer between stores and product movement in general, which translates into a lower carbon footprint for your organization.

- More sales and profits: in highly competitive retail environments, any improvement can translate into significant gains for the organization.

Looking for a robust software solution for your retail business? We can help you.

Trying to improve results in such a competitive environment as retail requires the best tools.

If what you have read here sounds interesting to you, at Holistic Data Solutions we can help you with a customized planning and BI solution, integrating all the potential that Artificial Intelligence can bring. If you want to talk to us, please contact us.

Related Articles

In a context like the current one where financial instability and market volatility are so present, it is normal that [...]

Board International was founded in the 1990s with the aim of being a Self-Service Analysis and Reporting, which goes through [...]

Time and money. If we were to carry out a market survey and ask finance directors, entrepreneurs or heads of [...]